Optical Bonding Solutions

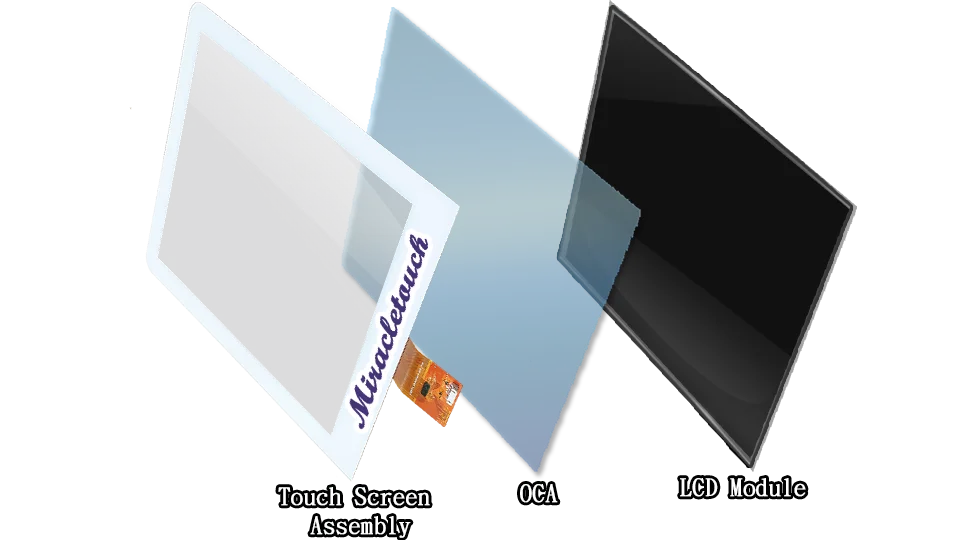

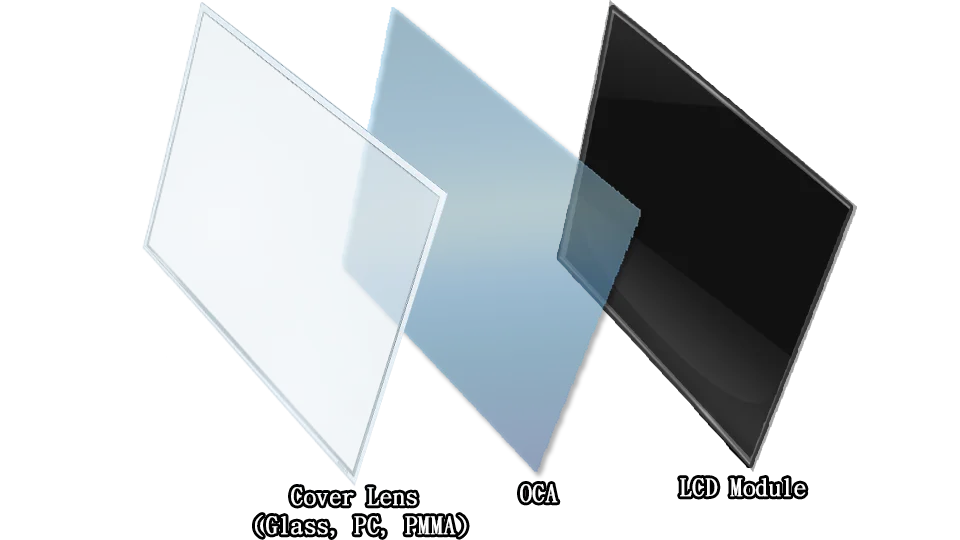

- To apply optical bonding, an agent is used, usually chosen between optically clear adhesive (OCA), or the liquid optically clear adhesive (LOCA), otherwise known as the optically clear resin (OCR).

- The OCA or the LOCA is then filled between the touch screen and the LCD module, which is the most commonly use of optical bonding.

-

Whether OCA or LOCA is chosen depends of the application of the product or the LCD used.

-

-

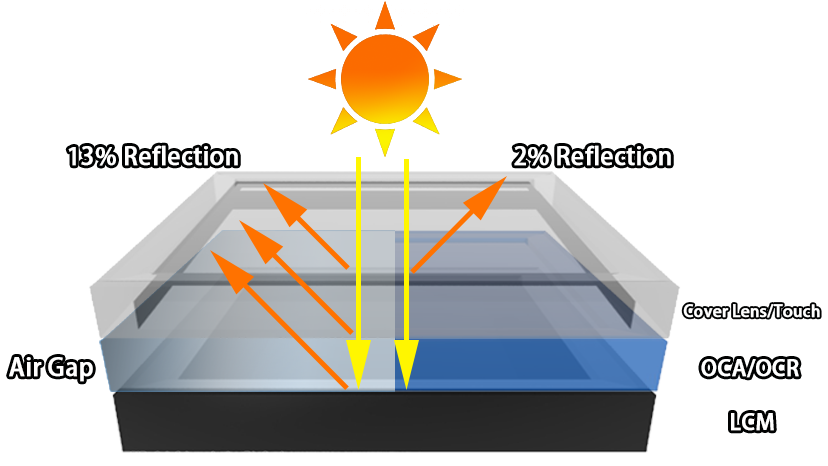

By applying this process, the air gap is eliminated and therefor the reflective index is reduced and brightness of the display increased, resulting in enhanced visibility.

-

- Besides of enhancing optical performances, it also provides multiple benefits such as increasing impact absorption and preventing moisture from forming inside the module's gap.

-

-

Which is why optical bonding is not only useful for applications that requires better performing display, but also a commonly sought out solution in applications demanding ruggedness or environmental resistance.

-

- Miracletouch's provides in-house optical bonding services in our own facility located in Taiwan, where we also manufacture the touch screens.

-

- Our total solution provides an high FPY rate and very cost effective reworking system.

-

-

Besides the standard solutions, we also provide UV resistant and wide temperature solutions for different applications.

-

- Bonding methods may differs between resistive and projected capacitive touch screen and can be applied to products up to 24".

-

- Please kindly contact our sales department for more details on our optical bonding services.